Precision manufacturing

Built to Print – built to last

Component, assembly or complete machine? The customer's idea and construction plans always take centre stage - flexibility and scalability included.

Our services:

Our assembly services:

Component, assembly or complete machines?

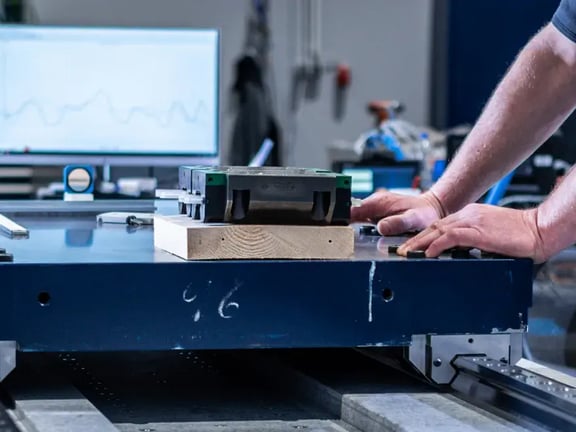

Our highly qualified employees, many years of experience and the associated expertise enable us to manufacture individual assemblies or complete machines for customers. For this purpose, the customer provides us with construction plans of his machine or machine parts.

We also develop individual assemblies independently and create the design plans ourselves. We hand over motion systems and basic machines.

You determine the scope of services. Our mechanical engineers always work together with experts on the customer side to ensure precise and efficient realisation.

- Flexibility and scalability: Outsourcing allows you to react flexibly to different order situations - without tying up your own resources in the long term.

- Concentrate on core competences: Focus on your core areas such as development, sales or design.

- Cost reduction and investment savings: Fixed costs for personnel, infrastructure and machinery are eliminated. At the same time, you avoid investments in expensive assembly technology.

Outsourcing of assembly services meets market demand! Component, assembly or complete machine? The customer's idea always takes centre stage. We make sure that everything runs smoothly - reliably, precisely and individually.

You determine the level of service.

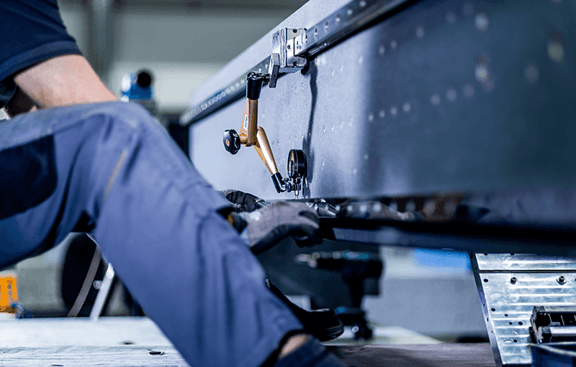

Our highly qualified service staff provide expert technical support to ensure high precision and flawless operation over the entire service life. We are happy to offer a locally set-up, including adjustment, alignment and measurement. The machine can also be readjusted at any time afterwards. Depending on requirements, specific maintenance contracts are developed together with the customer.

You can scale up as required and use us for the construction steps that you want to outsource. The decision and thus the cost control remain with you.

We breathe new life into your products.

- Measurement and set-up work on the machine geometry incl. test report

- Our service staff use the following measuring equipment: digital spirit level, autocollimator, Leica laser tracker, calibrated test standards

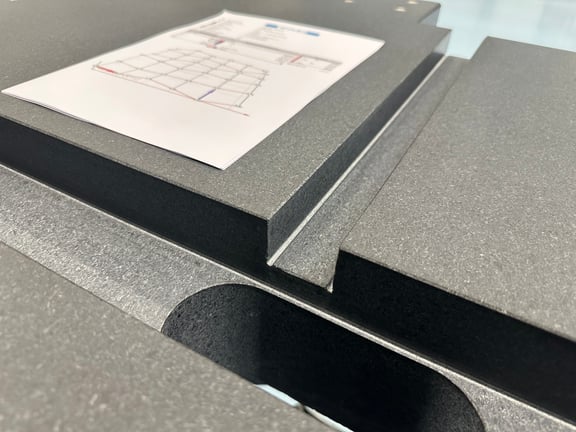

- Repair work on granite slabs to its original tolerance

- Lapping work on site with protocol according to environmental conditions

- Inserting additional threaded inserts

Reworking of existing customer workpieces

We rework customer workpieces regardless of the material. Benefit from the expertise of our design engineers.

We provide this service on request and charge on a time and material basis.

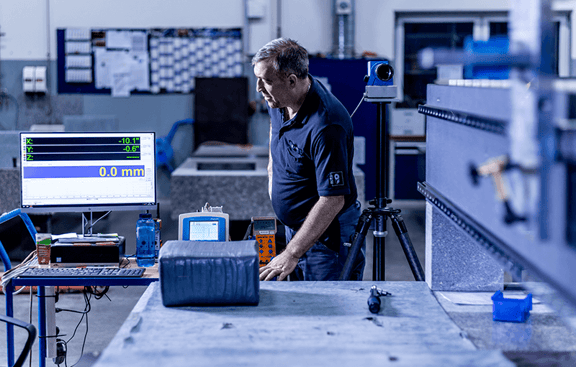

Measuring services

Our range of services also includes on-site measuring services. The results obtained from measuring and aligning existing machines are analysed directly by us.

If reworking is required, this is usually carried out at the customer's premises. Exceptionally, it´s sensible to bring your machine to us in Asslar.

We can also supply the measuring and test benches that we use for our quality assurance to customers.

We use various techniques for this:

- Optical measurement with autocollimators

- Laser interferometer and laser tracker

- Electronic tilt trolleys (precision water trolleys)

Logistics

We supply our customers with pre-assembled machine components or complete solutions directly to where they are to be used. For the most part, we use the company's own fleet of vehicles. We deliver 2-8 times a day.

Our REITZ promise: As many deliveries as possible with our own lorry!

- Own lorries enable flexible & cost-effective delivery

- Ensuring that the goods arrive correctly

- On-site inspection and installation or integration of machine parts into existing customer machines saves unnecessary complaints

- Complete installation on site and full final inspection by experts from REITZ Natursteintechnik