Precise by nature.

Granite machine components

REITZ precision granite is the basis for top technological performance - whether in semiconductor production, industrial automation or medical technology. We manufacture customised granite components for applications where every micrometre counts.

These industries rely on us:

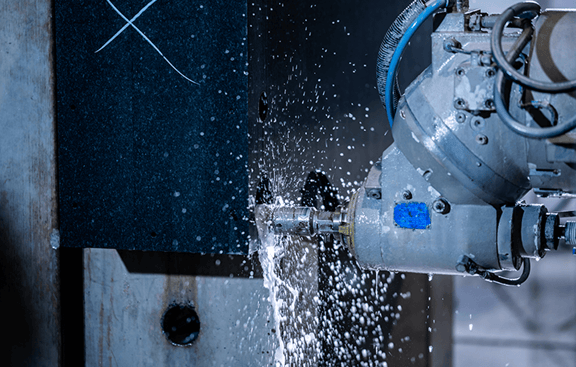

Machine tools

For high-precision machining processes in machine tool construction, granite offers a superior alternative to cast iron and steel.

Measurement technology

Granite is electrically non-conductive and non-magnetic – ideal conditions for use in electromagnetically sensitive test environments.

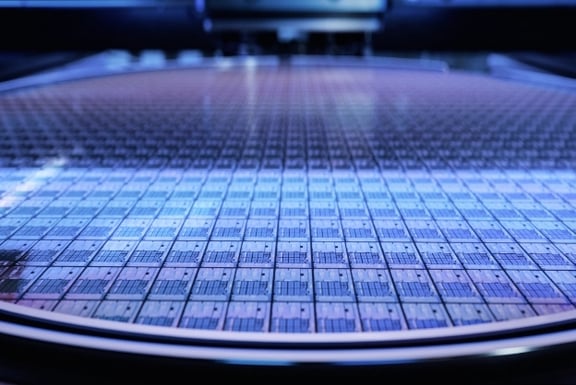

Semiconductor industry

Our granite components provide the perfect basis for high-precision production and inspection systems.

Optical industry

Optical systems require maximum precision, usually in the nanometre range. With our granite components, you can increase the quality and efficiency of your production processes.

Why granite in mechanical engineering?

We process granite in all dimensions into machine components. Our customers' success, continuous development and innovation are our top priorities. Due to its specific properties, granite is an ideal material for the manufacture of precision machines.

The advantages of granite lie in its physical and technical properties:

- Excellent thermal properties: low coefficient of expansion

- Active vibration damping on machine tools

- Low thermal conductivity

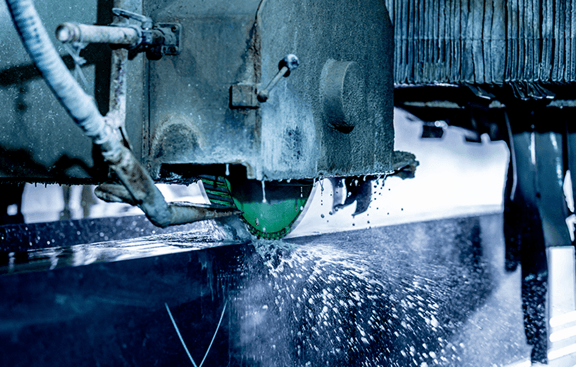

- Flat granite structure with high abrasion resistance

- Non-conductive and resistant to acids and bases

With granite, we achieve the highest precision in the micro range. We can achieve high precision down to 1μ! This makes granite the ideal material for precision machines - from coordinate measuring machines to general mechanical engineering with honing, grinding and milling. Various types of granite, such as Impala, are available depending on the requirements. We source high-quality hard stone from our partner quarries in Europe and South Africa.

Areas of application

Granite's excellent thermal and vibration-damping properties make it an outstanding material for precision mechanical engineering, e.g. for machine tools, measuring machines, machines for electronics production, optical machines and measuring and test benches. It is used in special machine construction and for parts with simple geometries in mass production.

We supply machine components with dimensions of up to 12,000 x 4,300 x 1,500 mm (L x W x H).

On request, REITZ can also undertake partial or complete assembly according to customer specifications.

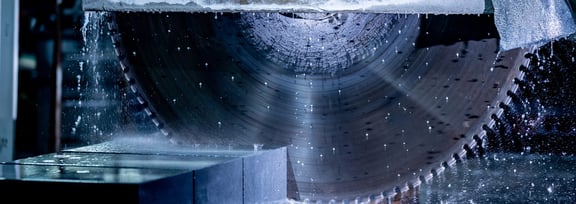

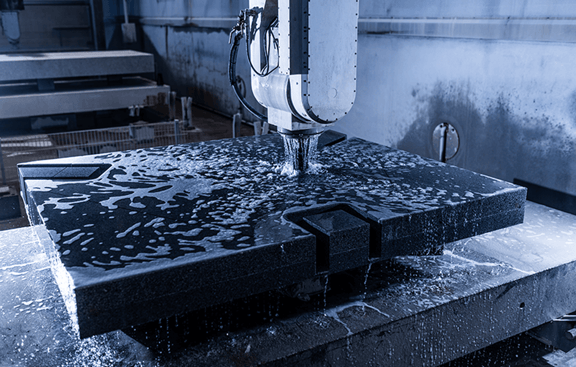

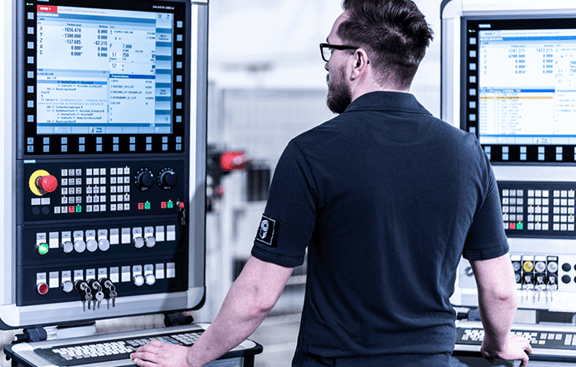

Production step by step

Crop

Surface grinding for flatness

Drilling for threaded inserts

Inserting the threaded inserts

Fine lapping for finishing

Quality control

Granite & concrete vs. steel in mechanical engineering

Mineral materials such as natural hard rock (granite) or high-strength concrete UHPC (Ultra High Performance Concrete) are becoming increasingly important in mechanical and plant engineering. Their properties make them convincing alternatives to conventional steel and cast iron constructions.

There are a number of reasons in favour of using the natural materials of concrete and granite: First and foremost, there are the outstanding physical properties, the high precision of the machine components and a very good ecological balance.

We live and love the millions of years old material stone, on the basis of which we manufacture high-precision machine components and complete systems for many everyday products.

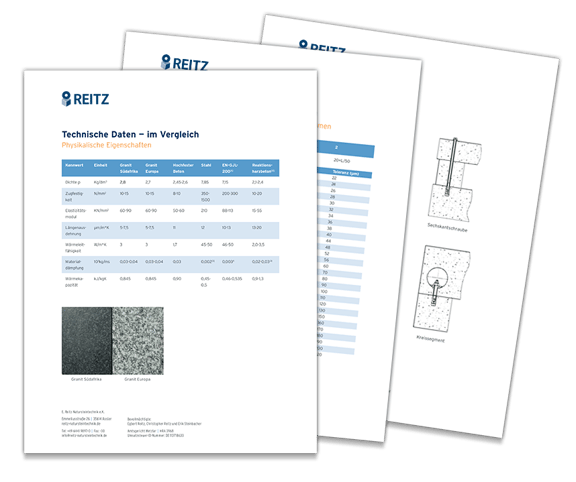

Need technical data sheets?

Download our technical data sheets on the physical properties and flatness tolerances of natural hard stone now!

Download PDF now!

We build components for the following machines:

- Highly dynamic precision machine tools (grinding, turning, drilling, milling)

- Optical machines

- Measuring machines

- Test benches

- Fundamente

- Machines for aerospace technology

- Machines for electronics production

- Precision laser processing machines

- Inspection machines

- Printing machines

Measuring and test benches

Coordinate measuring machine for quality assurance

We find that µ!

We can also supply the measuring and test benches that we use for our quality assurance to customers.

We utilise various techniques for this:

- Optical measurement with autocollimators

- Laser interferometer and laser tracker

- Electronic tilt trolleys (precision water trolleys)

High-strength concrete - special requirements for special solutions

Machine components made of concrete

High-strength concrete has similar properties to granite in terms of temperature and vibration damping. It scores highly in terms of price when producing large quantities. Due to its mouldability, it offers many design options.

Elements required for the function can be integrated into the moulds. For example, cables, water drains, sensors, cooling systems or hydraulic lines can be moulded into the components. We then speak of function-integrating machine frames made of cement-bonded mineral casting (UHPC-ultra high performance concrete).

Areas of application for concrete

Ultrahochfester Beton ist durch seine thermal properties (low thermal conductivity, low coefficient of linear expansion) and very good vibration damping (approx. 8 times better material damping than metal) for applications with high dynamics and high precision requirements.

UHPC is non-combustible and non-flammable. As a cement-bonded mineral casting, it can be recycled as construction waste. Part size and quantity as well as design and functional integration are the main factors that determine its economic use.

We realise machine beds made of high-strength concrete with cooperation partners.