Precision granite in machine tool construction

Granite offers clear competitive advantages in machine tool construction: high precision, stability and durability. REITZ not only supplies granite components, but also thinks in terms of solutions – individually, in partnership and future-orientated. This makes our granite the basis for the machines of tomorrow.

Machine tool construction

Precision for the highest demands

Machine tool construction is the backbone of modern manufacturing technology. It demands materials that guarantee lasting stability, excellent damping properties and high precision - even under the toughest conditions. Granite fulfils these requirements in a special way and has established itself in mechanical engineering as a high-performance alternative to classic materials.

Maximum precision

Why granite in machine tool construction?

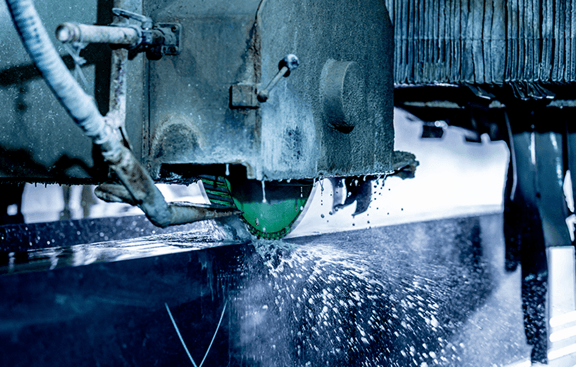

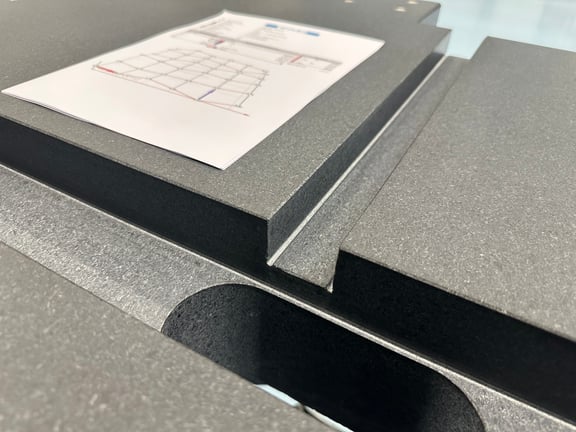

Granite is a natural material with many technical advantages that make it ideal for use in precision mechanical engineering. In machine tool construction, where every micrometre of deviation counts, granite enables a completely new level of quality. Its outstanding dimensional accuracy and dimensional stability, even over many years, make machine components more durable, reliable and low-maintenance.

- High dimensional accuracy and flatness for precise machining results

- Excellent damping properties that minimise vibrations and increase machining quality

- Thermal stability even with changing ambient temperatures

- Resistance to chemicals - resistant to oils, cooling lubricants, bases and acids

- Customised processing options for maximum adaptability to machine concepts

Precision granite for machine tool construction

We will be happy to advise you individually.

Fill in the enquiry form now